Best Way To Insulate A Tiny House

The best way to insulate a tiny house requires several products applied in the proper way. Your insulation not only deals with temperature but also humidity.

Insulation comes in many forms, but there are also vapor barriers both inside and out that need to be installed, depending on your climate.

Wall, roof, and floor construction is important to minimize thermal bridging.

The best insulator is non-moving air. All insulation products seek to trap air into non-moving pockets or bubbles.

There are two types of insulation: fibrous and foam.

Insulating a Tiny House Wall

There are several products you can use for insulating your tiny home. The best way to insulate your tiny house will depend on these factors:

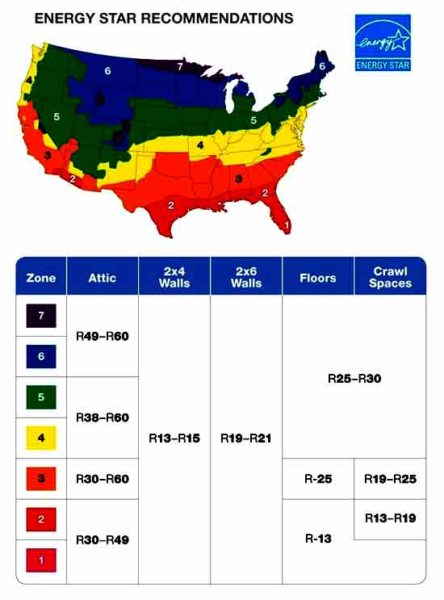

- Where will you be living? See the chart below to find the recommended R value your walls and ceilings should be.

- What part of the house you will be using it on? Floors, walls, and ceilings have different requirements.

- Your budget. See the fiberglass option below.

- Your desire to be “Eco-friendly.”

How much insulation will you need?

Closed Cell Spray Foam

This DIY product is recommended only for small applications. For an entire tiny house installation a professional company will cost a lot less. This product costs $1,009.72* for just 650 sq. ft.

Expandable spray foam is a very popular way to insulate tiny homes. Many builders think it is the best way to insulate a tiny house.

- It fills in every crack and pocket, sealing it completely.

- It becomes ridged when dried and adds structural integrity.

- Spray foam is impermeable to water. Resists moisture that can lead to mold or mildew.

- It never settles or loses its shape over time.

- The R rating is 6 per inch thickness. That will give you an R-21 rating for 2×4 walls.

- It’s comparatively lightweight.

Why wouldn’t you use spray foam insulation?

- Super expensive. Could be four to twenty times (depending on thickness) more expensive than fiberglass.

- Really toxic during the application process. You’ll need to wear a respirator, goggles, and gloves during application. A hazmat suit is also a good idea. Can release toxic fumes if it burns. This is not DIY material.

- The foam emits a gas during the curing process. If the chemicals are mixed improperly it could emit gas forever, rendering the home uninhabitable.

- The foam cures and hardens quickly. You need to know what you’re doing and apply it fast.

- You need to make sure that everything that needs to be done in the walls is finished before application. Trying to run wires or plumbing later will be a real pain.

- Spray foam can trap water inside and does not allow a wall to breathe.

Always have a professional company with a good track record spray your tiny house with foam insulation.

Always have a professional company with a good track record spray your tiny house with foam insulation.

To keep costs down a thinner layer of spray foam can be applied, then traditional fiberglass insulation over it. This produces a great result.

Spray foam insulation comes in smaller cans and is perfect for the tiny home builder to fill cracks and gaps. If you packed cracks and gaps with fibrous insulation it would be compressed far beyond the point where it would have any insulation value. But Great Stuff Spray Foam will maintain its R value while effectively caulking the gap.

Good YouTube® video discussing the difference between using open cell and closed cell foam.

This video also goes into shows the burn rate for several types of insulation. See the image at the top of the page.

Fiberglass insulation is economical, lightweight, and efficient

Fiberglass insulation is economical and easy to install. You just use a staple gun. It comes pre-cut to fit between wall studs, floor joists, and ceiling rafters. There is no off-gassing of any toxic fumes. It’s available from every building material supplier.

Fiberglass insulation is economical and easy to install. You just use a staple gun. It comes pre-cut to fit between wall studs, floor joists, and ceiling rafters. There is no off-gassing of any toxic fumes. It’s available from every building material supplier.

You need to wear a dust mask and goggles when installing to avoid breathing in any small particles. A cold shower is recommend after an installation day to remove any small particles poking your skin, reducing any itching that may result.

Fiberglass insulation comes with or without an attached kraft paper vapor barrier that makes it a breeze to install. This backing keeps the batts in place so they don’t slouch down.

Fiberglass is frequently made from recycled glass, formaldehyde-free, and non-flammable. The paper backing is flammable but it’s so thin that’s usually not a factor in a fire.

Recycling fiberglass insulation

When a house is remodeled the old insulation if frequently tossed in the garbage. Some tiny house enthusiasts on a tight budget have insulated their homes with these scraps. As long as you make sure you are not transporting mold or other contaminates into your build, it should be fine. You may need to add your own vapor barrier if that is required, because the paper backing will be pretty chewed up.

Fiberglass insulation works best when puffed up to its fullest extent. Using scraps and/or stuffing pieces into small gaps reduces its effective R value.

Denim Cotton Insulation

Where do those holey jeans go when you wear them out? Not to the insulation factory. Denim insulation is made from cotton mill waste and some recycled cotton products. It’s actually a good choice for the ecologically-minded builder and has become a main-stream product. The Home Depot carries a large selection of sizes manufactured with totally recycle cotton.

To get an R-21 insulation value, the denim batt would need to be 5″ thick that weighs 6.7 lbs for a piece that is 16.25″ wide and 94″ long. The same size fiberglass batt will weigh 5.67 lbs, but you will only need about three inch thick fiberglass to get an R21 rating.

Denim insulation can absorb moisture. It has a tendency to compress and slouch down with time and vibration and it is flammable. Like any insulation that comes in pre-cut batts there will be gaps by every stud.

HaveLock® Wool Insulation

HaveLock® wool is real wool insulation. It is hypoallergenic and will not support mold growth. The most frequent use is for van conversions. Wool has an R value of 3.6 per inch. The best place to use this wool insulation is in high humidity areas because it manages humidity. It maintains its insulation value even when damp and will dry easily.

Because it is not widely available, you will need to order early and wait for delivery.

The waste is compostable. Do not confuse with “RockWool” which is made from steel mill slag.

ROCKWOOL R-23 ComfortBatt Fire Resistant Stone Wool Insulation Batt

ROCKWOOL COMFORTBATT is a semi-rigid stone wool batt insulation for exterior wood and steel stud applications in both new construction and renovations. It features a unique flexible edge designed to compress as the batt is inserted then spring back, expanding the batt against the frame studs to give a complete fill. This flexibility ensures the expected R-value is achieved and maintained. Non-combustible and fire resistant, COMFORTBATT will not develop toxic smoke or promote flame spread, even when exposed directly to a fire. It is also offers water and moisture resistance and excellent sound absorbency. COMFORTBATT is an effective way to improve a home’s energy efficiency. It is GREENGUARD Gold Certified and contributes to a healthier indoor environment.

Rockwool is the insulation used by “the #tinylab” guys in this YouTube® video because it fills in the studs perfectly. Then they use a better backing material inside the structure like the MemBrain product shown below.

Flame resistance of various insulation products

Here is an excellent YouTube® video that shows the different flammable characteristics of various type of insulation products.

Also see this YouTube® video for additional demonstration of insulation burning: Testing the burn ability of insulation in a wall.

Mitigating Thermal Bridging

Thermal bridging occurs wherever a stud covers the entire width of a wall. Wood studs can transfer heat from the inside of the house to the outside of the house, reducing your insulation value. Metal studs are even better conductors of heat.

I like metal framing because it saves weight but the thermal bridging properties need to be mitigated. Saving weight on a tiny house build is one of our foremost goals. I searched for a product that would stop thermal bridging and be lighter weight than traditional OSB sheathing.

SilveRboard R5 Radiant Acoustic Insulation weighs just 1.5 lbs per sheet. It is 1 inch thick but the weight savings and R5 insulation value is worth the inch of width you lose. It is a non-structural material, but used in conjunction with the ridged closed cell spray foam insulation and a structural covering on the inside of the walls you will have a very lightweight, well-insulated wall.

This foam board is glued into place and the joints taped. Use a slightly longer nail or screw to attach the exterior paneling. This will hold it firmly in place. You do not need to use an additional vapor barrier with this product.

Vapor Barriers

Everyone covers the outside of the home with a weather barrier like Tyvek. It’s code. In some climates a “smart” vapor retarder should be added to the inside of the wall.

“For extra protection against moisture, the Certainteed MemBrain Continuous Air Barrier and Smart Vapor Retarder is your weapon of choice. It lets wall cavities dry out to help prevent mold. In summer, when humidity is high, it increases permeability so that moisture can escape, as air tightness is maintained. In winter, when humidity is low, it continues to block moisture. Use MemBrain with un-faced insulation in place of kraft faced insulation or polyethylene. Not all climate zones require vapor retarders.” From Certinteed

“For extra protection against moisture, the Certainteed MemBrain Continuous Air Barrier and Smart Vapor Retarder is your weapon of choice. It lets wall cavities dry out to help prevent mold. In summer, when humidity is high, it increases permeability so that moisture can escape, as air tightness is maintained. In winter, when humidity is low, it continues to block moisture. Use MemBrain with un-faced insulation in place of kraft faced insulation or polyethylene. Not all climate zones require vapor retarders.” From Certinteed

Do I need a vapor retarder inside where I live?

If you live in a mixed climate – hot and humid with several heating months in the winter, you probably need a vapor retarder. Specifically, if you live in climate zones 4C (marine), 5, 6, 7 and 8 (see map above). Not sure your climate zone?

If you live in a climate that is hot and humid all year long you should not use a vapor barrier.

Ceilings and Subfloor

Kiva and Jake from Tiny Nest have produced a remarkable series of 85 YouTube® videos that you should watch. Here is episode 13 on roof insulation and venting. It continues into episode 15 as well. They also selected the RockWool product as the best way to insulate a tiny house.

You may now know more than the average contractor about the best way to insulate a tiny home. If you are having your home built for you, make sure your builder knows the details discussed on this page. If they argue about any of it, consider using a different builder.

Experienced Tiny Home builders are experts on tiny home infrastructure.

Before you insulate make sure you have completed your electrical wiring, network wiring, plumbing, heating cooling and venting.

More Pages of the Tiny Life Consulting Website You’ll Be Interested In:

Infrastructure for a Tiny Home